It's no surprise then, that rats have the run of the metro stations and sewers of our cities.

The most common species of rat in Europe and North America, is Rattus norvegicus. It goes by many names: the brown rat, sewer rat, wharf rat and street rat. Running cables through the tunnels, sewers and drains that they live in makes economic sense. But protecting this infrastructure from rodent damage is a real challenge.

‘Don't underestimate the damage rodents and mustelids can cause on railway cables’

When Sylvie Herniou steps into her office in Paris on an average working day, rats, mice and mustelids – the family of mammals that includes martens, weasels and ferrets – are never far from her agenda.

“Don’t underestimate the damage rodents and mustelids can cause to railway cables,” she says. “The consequences can be expensive. And the amount of cable, including fibre optic, is increasing fast,” she adds. “Companies facing this problem soon realise that prevention is more cost-effective than repairs.”

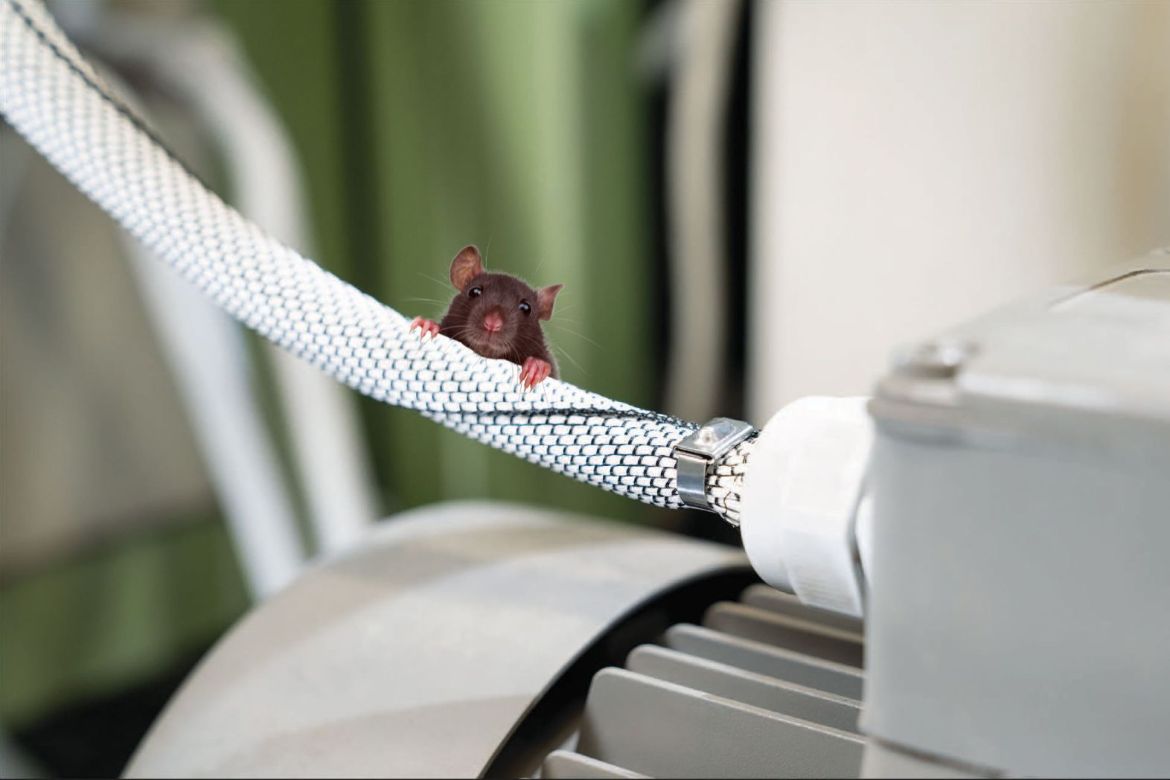

“Our solution to this growing challenge is Twist-In RR. It's the ‘Rodent Repellent’ addition to our Helagaine range of protective woven sleeving: a safety feature against gnawing teeth. That's a different approach to other products, which rely on chemicals. The problem with chemical repellents is that the effect may wear off over time. Renewing that costs repeated time, money and effort”, she explains.

‘The problem with chemical repellents is that the effect may wear off over time’

The key to the reliability of Helagaine Twist-In RR lies in glass fibre filaments. These are woven into a robust, flexible polyester sleeve with self-closing properties. The material has good resistance to acids, solvents, UV, weathering and micro-organisms. Thus it is suitable for tough environments such as sewers, tunnels and rail infrastructure. "We designed Twist-In to be easy to retrofit around cables", adds Sylvie Herniou. "It self-wraps and is very flexible. That makes it more effective and practical than split-corrugated tubing."