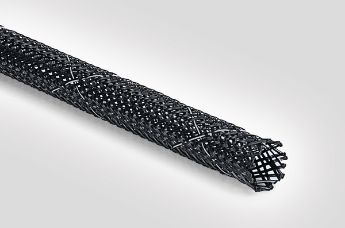

Braided sleeving is mainly used to bundle and protect cables. Standard wrap-around sleeves, which can be applied and removed with a single handle, are ideal for this purpose.

Other applications require braided cable sleeves with special material and properties. For example, there are heat-resistant fabric sleeves that withstand high temperatures.

Whether you are buying for IT or industrial infrastructure, you will find the right fabric hose for your application below.

The flame-retardant HFRV0 braided sleeving is designed for use in environments where fire protection is essential. It is flame-retardant according to UL 94V0, halogen free and used for example in the following industries:

Made from robust polyester, is highly resistant to abrasion and also highly flexible.

The product variant HEGPETFR is a flexible and expandable sleeving solution that is particularly suitable to the requirements in the automotive and rail industries. It is flame-retardant according to UL 1441VW-1, halogen free and is EN45545-2 certified.

Twist-in-EMIZ woven sleeving, made of tin-plated copper and polyester, attenuates high frequency electromagnetic interference on sensitive wiring and diverts induced shield currents to a grounding system. This woven sleeve is designed for confined spaces where multiple cables run in close proximity.

This EMI shielding sleeve is crafted from tin-plated copper wires and polyester monofilament. It begins as a flat-woven ribbon, which is then thermoformed into a tubular shape for easy installation. In other products of this kind, parallel wires incorporate air gaps, which can cause thin-slot leaks and reduce shielding efficiency over long distances and at high frequencies. To avoid this, the Twist-In-EMIZ braided sleeving – where a warp conductor is integrated into the weft, ensuring an equipotential bond that maintains shielding continuity – was developed and patented.

Common applications for this EMI shielding sleeve include high-density cable environments, such as rolling stock applications, where minimising cable separation distances creates more space for passengers and/or a second floor. For weight-sensitive applications, the Twist-in-EMIZ woven sleeve can be optimised by inserting the warp thread every six meshes, balancing performance and efficiency.

HelaGaine Twist-In self-wrapping polyester sleeving is perfect for installation on pre-terminated wiring or retro fitting. It can be opened with a single movement.

Twist-In guarantees easy, simple cable bundling as well as removal without having to disassemble connectors or fittings. While it is primarily designed for optimal abrasion protection, it is also used for cable management. Individual cables can be easily branched out while the entire cable harness is closed and protected. HelaGaine Twist-In is often used in the production of industrial machinery, electronics, electrical engineering and in the automotive industry – but also as wire protection for home office and entertainment systems.

For environments where high fire protection is required, the flame retardant protective Twist-In-FR is the sleeving of choice.

Wild animals pose a threat to your installations. HelaGaine Twist-In-RR is designed to protect cables and hoses from rodents by being made of glass fiber and polyester multifilaments. This sleeving also offers excellent characteristics in terms of abrasion resistance, UV, vibrations and impacts protection.

HelaGaine Twist-In-RR is also frame-retardant and provides protection for harsh environments such as underground installations and sewage systems.

Among other fields of application, HelaGaine Twist-In-RR is also used in the following industries:

Braided sleeves help you to organise and bundle cables and wires. But that's not all: Sleeving is available in a variety of materials and with a wide variety of properties for different applications: from flame-retardant braids.

While standard solutions are used at home and in IT environments, braided sleeving with special properties is used in almost all industries – including the automotive and rail industries and the defense aerospace industry.

Due to their flexibility, most braided sleeves can easily be pulled over bundled goods manually by the push- and slide method. With scissors or a hot cutting tool, you can simply cut your fabric sleeve to the right length (see details below).

HellermannTyton wire mesh cable braids are supplied with a removable inner tube to make it easier to push the sleeving over wire harnesses.

In contrast to tubular braided sleeves, there are also wrap-around woven sleeves. These are particularly suitable for quick installation, but also for retrofitting. HellermannTyton offers slit self-wrapping sleeving such as Twist-In.

Cutting braided sleeving with conventional scissors is likely to fray the ends. This is why the use of a hot knife is recommended for low to medium quantities. With tools like the industrial hot knife you can cut braided sleeves cleanly – without any fraying.

Within a few seconds the cutter is ready for use – all it takes is the push of a button. The metal knife is heated and cuts through the sleeve. The cut ends fuse together with their direct neighboring threads and form a new fray-free end.