Cable tie guns are not all the same – and for good reason. While some cable tie processing tools are suitable for areas that are difficult to access, other cable tie guns must function without electricity when used in mobile applications. There are also the durability and efficiency requirements of modern series production to consider: Cable tie tools must always be reliable and convenient, even during long-term use.

That’s why HellermannTyton offers a comprehensive range of cable processing tools.

Cable tie guns are the ideal solution for optimum tensioning and cutting of cable ties flush to the cable tie head. They eliminate the sharp snags that conventional wire cutters leave behind. Cable tie guns also help accelerate bundling processes and professionalise the tying of cable ties made from various materials and sizes.

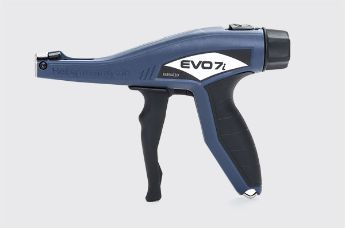

See in this video how to cut cable ties safely and without sharp edges using a professional cable tie gun. The EVO7i cable tie gun featured is one of the most lightweight yet robust manual cable tie enough for industrial processing of cable ties:

With the EVO family of cable tie guns, HellermannTyton offers you the most ergonomic and durable manual cable tie tools on the market. Comfort and function are combined to provide high-quality repeatable cable tying results at a wide variety of tension settings.

The technology in the EVO7i and EVO9i cable tie tools significantly reduces the amount of force required to tension and cut cable ties. The EVO family cable tie processing tools feature quick adjustment for changing between tension setting ranges.

Your advantages:

With its lightweight, ergonomic design, the MK9SST cable tie gun is an ideal tool for applying the stainless steel cable tie series. Although it is used for applying stainless steel cable ties, the MK9SST cable tie gun enables work to be carried out without operator fatigue.

For easier handling the tensioning is fully adjustable by means of a quick two level control with an additional fine setting. This feature means that

damage to the bundled materials is easily avoided. The cable ties are automatically cut off flush with the head when the preset tensioning level has been reached.

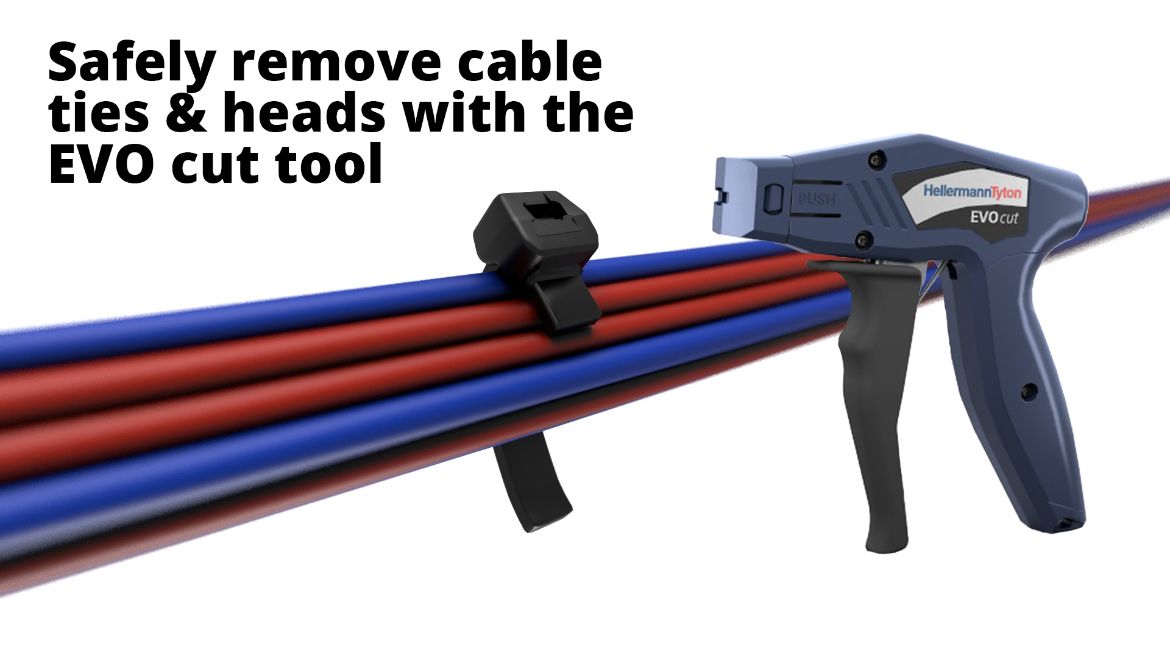

The cable tie cutter EVO cut is used for the safe removal of plastic cable ties. So fare cable ties have been removed with a standard side cutter that runs the risk of damaging the cable, with the new EVO cut cable tie removal tool the wire insulation remains intact.

The EVO cut zip tie cutter is ideally suited for large-scale industrial applications in cable assembly. It features a lightweight, ergonomic housing made from glass-fibre-reinforced polyamide, making it easy to operate with one hand.

Its key benefits include safe cable tie removal without damaging cable insulation and versatile cutting options that allow the user to cut either the strap or the head. To ensure that only the cable tie is cut - and not the cable bundles - a matching nosepiece is required, depending on the tie’s width and thickness. For this reason, the zip tie cutter is available with eight different nosepieces.

Eight nose pieces provide great flexibility for users looking to reduce the risk of damage to expensive wiring harnesses during maintenance and modification.

With the correct nose piece in place, the EVO cut’s integrated shearing blades cut only the strap or head of the cable tie, protecting the underlying cable insulation. This ensures that users can safely and accurately remove cable ties at any point along the bundle, avoiding inadvertent damage to surrounding components.

| Nosepiece | max. width tie | max. thickness tie | T-series | OS-series | X-series | CTT-series | PEEK |

| S: strap | 3.6 mm | 1.2 mm | T18, T30 | T180ROS, T30ROS | X20 | CTT20 | PT2A |

| M: strap | 4.8 mm | 1.3 mm | T40, T50, T80 | T50ROS | X80 | CTT60 | PT3B, PT220 |

| L: strap | 7.8 mm | 1.8 mm | T120 | T120ROS | X120 | - | - |

| Nosepiece | max. width head | max. length head | T-series | OS-series | X-series |

| S: strap | 4.6 mm | 4.8 mm | T18 | - | - |

| M: strap | 6.1 mm | 6.1 mm | T30 | T18ROS, T30ROS | X20 |

| L: strap | 8.3 mm | 7.6 mm | T50, T80 | T50ROS | - |

| Nosepiece | max. width tie | max. thickness tie | KR-series |

| KR6 | 6.1 mm | 2.0 mm | KR6 |

| KR8 | 8.0 mm | 2.0 mm | KR8 |

All nosepieces are securely attached to the EVO cut and can be easily changed using a simple push system.

A light press on "Push" releases the locking mechanism and the front cap can be pulled off. The front nosepiece can be put back on just as easily.

TLC technology stands for Tension/Lock/Cut. This bit of technology makes all the difference in the EVO7i and EVO9i cable tie guns.

1. Tension

The cable tie is tensioned to the preselected tensile force.

2. Lock

Once the selected tensile force is reached, the cable tie gun automatically clamps the cable tie strap. The manual force usually required to keep the cable tie tensioned is no longer required.

3. Cut

All the user has to do is pull the cable tie gun lever back gently. Very little force is required for the flush, smooth cut.

The benefit of the TLC technology in the EVO cable tie tools is immediately obvious to anyone used to conventional cable tie guns. Locking the tensioned strap before the cut reduces the mechanical strain on the tie, the blade and the operator’s muscles. The lack of recoil helps minimise repetitive strain injuries when operators manually tie thousands of cable ties per shift.

Cable tie guns are often used when cable ties are processed in large quantities. The aim is to make it easier to tie large quantities of cable ties quickly and cut off the excess strap flush to the tie head. Cable tie guns also help tension and cut cable ties in hard-to-reach spaces, or at awkward angles, using one hand.