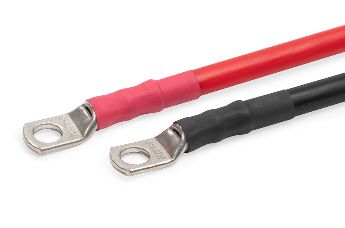

HellermannTyton offers engineers and electricians a wide range of cable lugs and links which are designed to provide secure connections in power distribution, earthing and low voltage applications across various industries.

Our copper cable crimp lugs and links are manufactured from high-conductivity copper, ensuring minimal energy loss and delivering superior mechanical strength with excellent resistance to corrosion, vibration and mechanical stress.

In a variety of sizes, manufactured with 99.9% pure copper with a tin-coating of 5-10 microns making them suitable for electrical installation and termination in harsh environments such as oil, gas mining and solar applications. All copper crimp lugs and links undergo a tinning process followed by annealing to ensure optimal performance, durability and to prevent cracking when exposed to compression and stress. All HellermannTyton cable lugs and links are REACH compliant and comply to Australian and New Zealand standards 4325 Part 1: 1995.

These copper cable lugs are a general-purpose lug, suitable for a wide range of applications and industries. They are manufactured to suit Australian standard metric cable sizes and feature a straight barrel design that allows for easy insertion of wire conductors.

Additional features

Our Bellmouth copper lug is suitable for applications where the termination of flexible cable is required. These lugs are commonly used in electrical switchboards as well as in the automotive, mining, and solar industries where flexible or finely stranded cables are required. They are designed with a flared (bell-shaped) barrel which allows for easy insertion of fine-stranded cables, which can splay out after stripping.

Additional features

Also known as narrow palm cable lugs, these are specifically designed for applications that require space-saving or confined installations. Similar to our Bellmouth lugs, they feature a flared (bell-shaped) barrel to enable easy cable insertion. However, the palm is narrower, allowing the lug to fit into tight spaces. These lugs are engineered to fit closely and securely onto circuit breakers, helping to reduce the risk of electrical flashover between phases or to ground.

Additional features

These copper cable lugs are used to terminate copper conductors in various outdoor applications. Featuring a long barrel and short palm, they are designed to provide increased surface area for effective contact and crimping, while ensuring strong mechanical performance under vibration and stress. They are ideal for installations where spatial limitations exist, and the short palm helps reduce the risk of flashover.

Additional features:

These sealed cable lugs provide higher structural integrity and structural resistance. They are an ideal choice in the mining and rail industry where the conditions require robust and reliable connections due to exposed elements. They are designed with a large surface area; this allows the spread of mechanical and thermal strain which reduces the risk of termination failure.

Additional features:

Our copper crimp links are a general-purpose cable link or sleeve which can be used in various applications and industries. They’re designed to join two copper conductors of the same size in-line. They are an ideal choice when no termination point is required.

Additional features:

Copper Reducing links are designed to join conductors of two different sizes. They provide a reliable and clean transition between different cable diameters. They are multipurpose and can be used in various applications and industries, including switchboards where varying wire sizes are common.

Additional features:

Aluminium cables are becoming an increasing alternative to copper for various electrical projects due to their cost effectiveness and lightweight properties. HellermannTyton offers a range of Aluminium to Copper solutions that are suitable for a variety of electrical installations. These are utilised widely in underground power distribution and on utility solar applications. Our Bi-metal cable lugs and links are made from an Aluminium rod and 99.9% pure copper and are joined through friction welding. This bonds the aluminium and copper together to prevent galvanic corrosion and ensures reliable long-term performance. All HellermannTyton Bi-metal cable lugs and links are REACH compliant and comply to Australian and New Zealand standards 4325 Part 1: 1995.

These cable lugs are used to terminate an aluminium cable to a copper busbar. They’re designed to withstand high current-loads, handle harsh conditions and mechanical stress. Commonly seen in utility networks, solar farms, substations and industrial power systems, however, can be used for various applications and industries.

Additional features:

When termination is not required, a Bi-metal reducing link is used to join an aluminium conductor to a copper conductor in-line. They provide reliable and efficient connections between varying sizes and ensure seamless transition in power of the dissimilar materials. They’re designed to withstand high current loads, temperature fluctuations and harsh environmental conditions making them suitable for utility networks, substations and industrial power systems.

Additional features:

When working with electrical installations it is important to ensure that there is safe and reliable termination – this starts with using the right tools. That’s why HellermannTyton offers a comprehensive range of manual crimping tools for cable lugs. Our tools are designed for ease of use, enabling quick, reliable and secure connections while maintaining high performance under demanding conditions.

Advantages:

Tin plating protects the copper from oxidation and corrosion, especially in harsh or moist environments. It aids in the durability, reliability, and versatility of the copper cable lugs, making them suitable for a wide range of applications and industries.

To select the correct cable lug or link, ensure it precisely matches the conductor’s size and material - whether copper, aluminium, or bi-metal. Take environmental conditions into account: use tinned or stainless steel lugs in corrosive environments, and insulated lugs where additional protection is required. Always match the lug’s current and voltage ratings to the application and use the appropriate crimping tool as specified by HellermannTyton. Confirm compatibility with the terminal stud size, and ensure the product complies with relevant standards such as AS/NZS 4325 or IEC 61238-1. For critical or high-vibration installations, opt for long-barrel or double-crimp lugs. Lastly, verify that compaction meets HellermannTyton’s specifications for optimal performance and reliability.

A cable gland and a cable lug serve different purposes in electrical installations. A cable gland is used to securely seal and protect a cable as it enters an enclosure, providing strain relief and maintaining the ingress protection (IP) rating against dust, moisture, and mechanical stress. It is commonly used in panels, junction boxes and outdoor equipment. In contrast, a cable lug is used to terminate the end of a cable, allowing it to be securely connected to electrical terminals, busbars or equipment. Lugs ensure a reliable electrical and mechanical connection and are typically made of copper or aluminium, often tin-plated for corrosion resistance. While cable glands focus on sealing and protection, cable lugs focus on termination and electrical conductivity. Both can be used in a wide range of applications and industries.