RFID (Radio Frequency Identification) tags are small electronic devices used for tracking and identifying objects. RFID tags come in various shapes and sizes, in cable ties, hard tags, markers and labels. RFID tags can be passive – powered by the reader's signal – or active – with their own power source.

HellermannTyton offers passive RFID tags, which use a microchip and antenna to receive energy from a reader's RF signal, allowing data transmission without an internal power source. Key benefits of passive RFID tags include: simplicity, small size, and long lifespan.

These RFID tags are ideal for non-contact, non-line-of-sight applications such as inventory tracking, warehouse operations, supply chain optimisation, and asset tracking.

Choosing the right RFID tag for your application is essential to ensure optimal performance, accurate tracking, and seamless integration into your specific environment:

HellermannTyton RFID tags are available in various frequency ranges, including low frequency (LF), high frequency (HF), and ultra-high frequency (UHF), each suited for different applications.

Radio frequency bands established by international standardisation:

| Abbreviation | Frequencies | Wavelength in free space | |

| Low frequency | LF | 30kHZ - 300kHz | 10km - 1km |

| High frequency | HF | 3MHz - 30MHz | 100m - 10m |

| Ultra-high frequency | UHF | 300MHz - 3GHz | 1m - 100mm |

Low frequency (LF) RFID tags operate in the frequency range of 30 to 300 kilohertz (kHz), typically between 125 and 148 kHz. These tags work by capturing a low-frequency radio signal emitted by an RFID reader, which induces a small electrical current in the RFID tag's antenna.

The primary advantages of LF RFID tags include their readability in challenging environments, making them suitable for applications requiring close proximity scanning.

HF RFID tags function just like LF tags, however they operate within the frequency range of 3 MHz to 30 MHz, typically 13.56 MHz. HF RFID tags offer a moderate read range of up to about 1 meter and faster data transfer rates compared to low frequency (LF) tags. Thus, they are commonly used for inventory management.

Ultra-high frequency (UHF) RFID tags operate within the frequency range of 300 MHz to 3 GHz, typically between 860 and 960 MHz. Their most prominent advantages over LF and HF RFID tags are a long read range and high data transfer rates. Due to this, UHF RFID tags play a crucial role in providing efficient and reliable identification and tracking in inventory management, supply chain logistics, and, asset tracking.

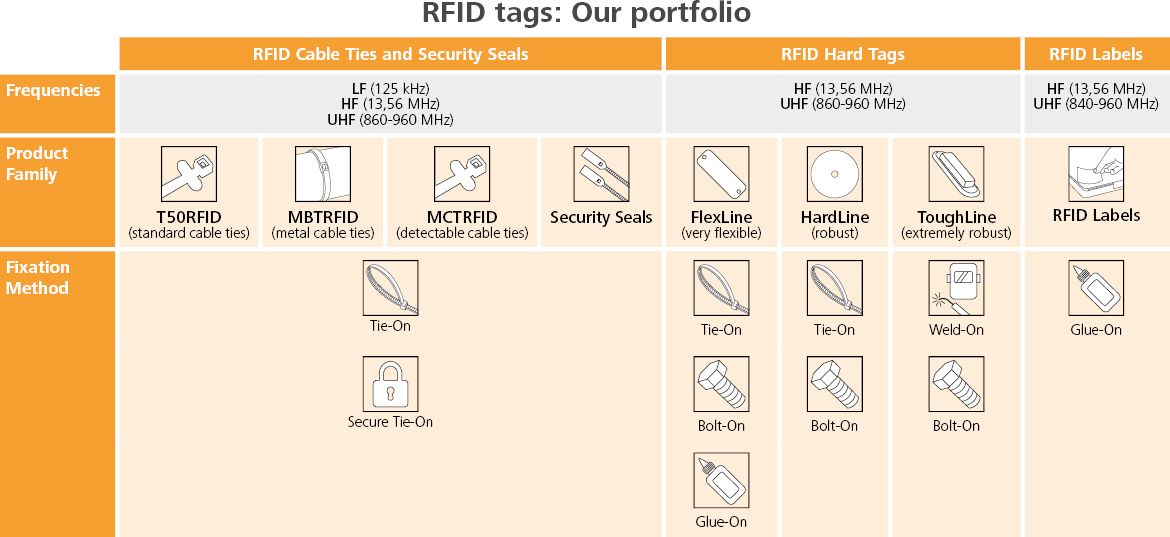

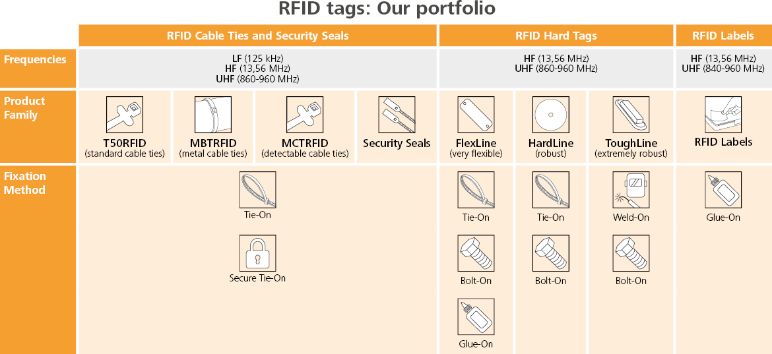

RFID cable ties offer a simple, fast, and durable solution for attaching RFID transponders to any object or location, whether permanently or temporarily. Engineered with unique properties for a wide range of applications, these cable ties combine material and manufacturing expertise to adapt to almost any environment.

RFID tags in cable ties offer a smart and efficient way to identify and track products quickly and accurately. The nylon T50 RFID cable ties are embedded with an RFID transponder, combining the benefits of traditional cable ties with advanced RFID technology. The series is available in different colours, lengths, and frequencies: from low frequency for read-only applications and high frequency for rewritable use.

In industries such as food, chemical, or pharmaceutical, it is crucial to be able to detect plastic RFID tags. To facilitate this, a percentage of metallic elements (magnet/X-ray) is incorporated into the backing material of the cable tie, allowing detection by metal scanners. HellermannTyton MCT RFID detectable cable ties are available in HF and LF.

For applications requiring high tensile strength, high temperature resistance, and durability, plastic RFID cable ties may not be sufficient. HellermannTyton MBT RFID metal cable ties are made from SS316L stainless steel and include a slide-on carrier for an HF or UHF RFID transponder, allowing them to endure severe conditions.

The HS30LM RFID security seal is designed to simultaneously identify, bundle, and secure items without the need for screws or adhesives. Available in UHF RFID tags, it is resistant to harsh environments and can be customised with logos and/or barcodes for contactless reading.

Our portfolio of RFID hard tags includes transponders with a wide range of capabilities. These RFID hard tags can be distinguished by the materials, the design of their structure, the attachment methods, and the frequency. HellermannTyton offers RFID tags that can be mounted using cable ties, screws, rivets, bolts, nails, adhesives, by glueing, and even welding. They are categorised into the following three series:

FlexLine RFID hard tags are robust, versatile identification elements designed to meet a wide range of applications. Constructed from resilient, flexible materials, the tags in the FlexLine series are designed to resist deformation and brittleness under mechanical stress, ensuring durability and longevity.

Due to their flexibility, the FlexLine RFID hard tags easily conform to curved surfaces, ensuring a secure fit on cables, pipes, and hoses. The design of FlexLine RFID tags includes a variety of mounting options, they can be easily and securely installed using cable ties or bolts.

These flexible RFID hard tags are available in UHF.

HardLine RFID tags are robust identification elements constructed from rigid, impact-resistant materials, making them highly durable and suitable for a wide range of industrial applications. These tags are designed to be securely mounted on various substrates, including plastic, glass, metal, or wood.

HardLine RFID tags provide a stable and secure identification solution for heavy-duty equipment. Designed for bolt-on application, these robust tags withstand mechanical stress and extreme conditions, ensuring long-term reliability where other materials fail.

Thanks to their durability, HardLine RFID tags can be fixed to various objects, making them ideal for tracking pallets, tools, machines, and both semi-finished and finished products. They are also well-suited for labelling disposal bins, including garbage cans and containers. Operating on UHF and HF frequencies, these tags excel in harsh environments and demanding applications.

ToughLine RFID tags are designed for maximum durability and reliable identification in the harshest conditions. These RFID tags feature mounting holes for secure attachment using bolts, screws, and can also be affixed by welding, providing versatility for various surfaces.

These tags deliver unmatched durability and reliability in extreme temperatures and harsh outdoor conditions where durability is critical. Designed for permanent tracking, they withstand rough handling while ensuring clear, long-term tracking. Ideal for pallets, metal transport containers, machinery, and waste management bins.

Self-adhesive RFID labels are often the easiest and most cost-effective solution for tracking and identifying assets digitally. Featuring an insulating layer, these labels ensure reliable RFID performance, providing fast, safe, and resilient data capture. Their compatibility with thermal transfer printers adds to their versatility, allowing for customisable visual identification, enhancing data accuracy and management efficiency.

Adhesive RFID labels can be produced in various sizes, shapes, and colours, allowing for additional functionality. Available in both HF and UHF versions, our RFID labels can also be made from a variety of materials provided with a permanent adhesive for permanent adhesion. Customers can choose from paper labels to extremely robust and durable PET labels. Even oils and chemicals cannot damage the most robust RFID labels in challenging environments.

The Tag 'n' Track Hens research project at the University of Rostock (Germany) showcases the powerful role of HellermannTyton’s RFID tags in improving animal welfare. Using our UHF RFID tags from the Flextag series, researchers are able to track laying hens in real time, gaining vital insights into their behaviour and interactions with food, water, and nesting resources.

Key benefits of the RFID tags in livestock:

This innovative application of RFID tags not only supports better animal health and welfare monitoring but also opens new opportunities for the technology in agriculture and beyond — demonstrating the versatility and scalability of RFID tags in demanding environments.

RFID (Radio-Frequency Identification) tags are used for a variety of applications across different industries for use cases such as inventory management, supply chain management, asset tracking, access control, transportation and logistics, and animal tracking. RFID tags provide a reliable and efficient way to track and manage objects, improving operational efficiency, security, and accuracy in various applications.

RFID (Radio-Frequency Identification) tags work by using radio waves to communicate with a reader, enabling the automatic identification and tracking of objects.

The lifespan of passive RFID tags is typically very long, often lasting from 10 to 20 years, and can be influenced by several factors such as environment, material, usage frequency, handling and technology. Passive RFID tags are often chosen for applications where long-term reliability is essential due to their long operational life and lack of a power source.

The read range of passive RFID tags varies based on several factors, including the frequency band they operate in, the power of the RFID reader, and environmental conditions. The longest range passive RFID tags typically operate in the Ultra-High Frequency (UHF) band, specifically between 860 MHz and 960 MHz.