At HellermannTyton we thrive on taking established design conventions for fixing parts and improving on them. So when we received a request for a more versatile way to mount and clamp cables and hoses on construction machinery we rose to the challenge. We applied our extensive cable tie design know-how to solve all the mechanical limitations of the conventional p-clamp that our customers told us about.

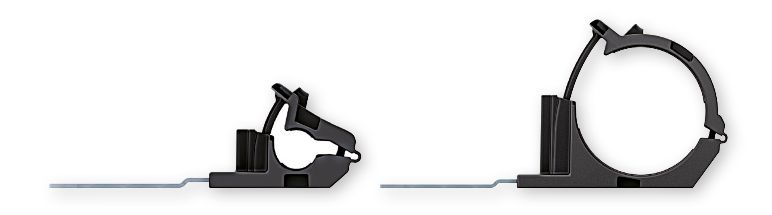

The result is the Ratchet P-Clamp. It is the most user-friendly, versatile and robust P-Clamp for fastening and fixing cables, wires, pipes and hoses on the market.

Especially for maintenance work, the Ratchet P-Clamp is the ideal solution: cables and wires can be replaced with ease, and without having to unscrew the product. All you need is a screwdriver to open the closure again. This means that the Ratchet P-clamp can be reused hundreds of times.

We matched the Ratchet P-Clamp features to the following usability requirements:

With the Ratchet P-Clamp you can now determine the desired route for your cables, hoses or pipes before the cables, pipes or hoses have even been delivered!

This two-stage operation also gives you the freedom to split the fastening and the fixing task in the time sense, or between different installers or contractors. You can even attach the clamps to the harness before it is installed.

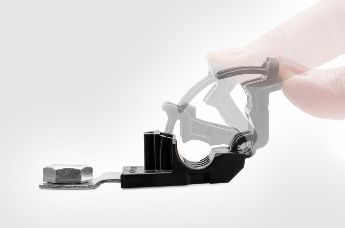

The Ratchet P-Clamp can easily by closed with one hand to the optimal diameter. The audible clicking as the ratchet assures the user that the clamp has closed securely. See how easy it is to work with in our video clip.

The Ratchet P-Clamp also meets the quality assurance needs of process engineers. An optional tension tab and HellermannTyton’s EVO series cable tie gun enables installers to close the p-clamp with exactly the same tension every time.

In contrast to plastic omega snappers, push-in clips or two-piece fixing clamps, we designed the Ratchet P-Clamp so that it can be reopened simply without having to dismantle the bundle from the fixing points.

This is a huge benefit for maintenance engineers, especially when cable harnesses need to be adapted or modified to fit new connection points.

Simply insert a flathead screwdriver in the slot and lever out the ratchet closure. The plastic material is especially toughened so that you can re-open and re-use the clamp time and again.

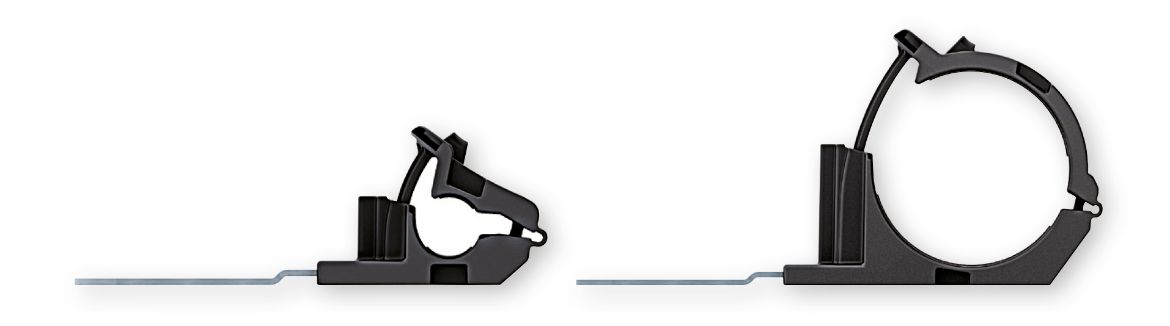

The Ratchet P-Clamp is available in four sizes that are all adjustable.

Part inventories can be significantly reduced and installers no longer need to carry a wide range of clips in different fixed diameters.

With just four Ratchet P-Clamps and optional soft inserts you can do without dozens of aluminium clamps and metal or plastic p-clips.

All four Ratchet P-Clamps (for bundle diameters from 6,2 mm to 51 mm) are easy to combine on a single mounting point. The zinc-plated stainless steel mounting plates are available in different lengths and with four different mounting hole sizes (M6, M8, M10 and M12).

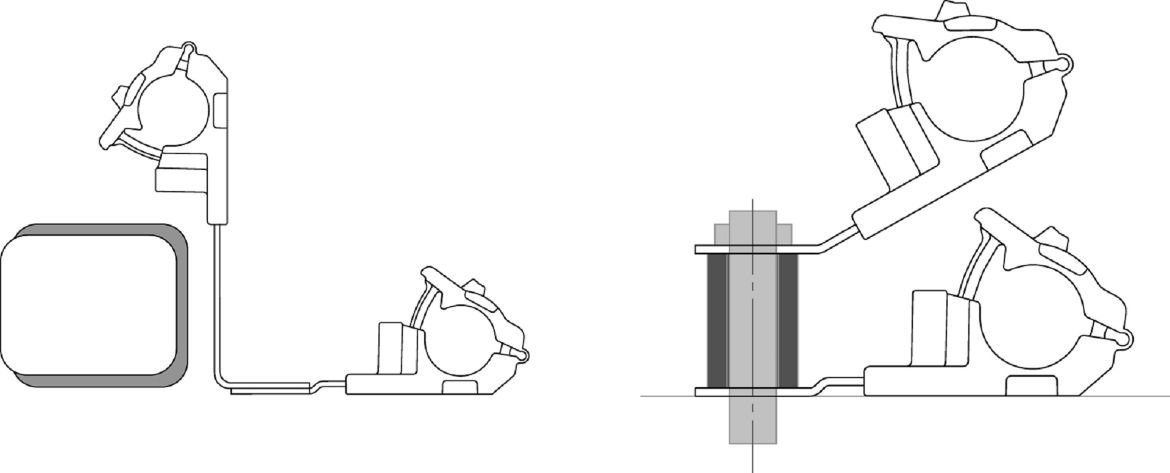

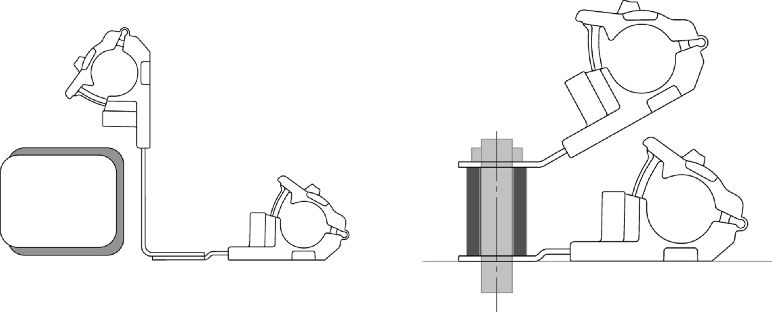

The robust stainless steel mounting plates also come in four different angles (offset 180° and 90° or raised 30° and 15°). This makes it possible to combine several clamps on one fixing point by stacking the mounting plates. Spacing your cable clamp mounting couldn’t be easier.

The variety of angles and mounting plate lengths and dimensions of the Ratchet P-Clamp make an endless number of alignments and configurations possible. Here are some of the most popular configurations that our customers are using:

Two clamps fixed face-to-face on one mounting point and two piggy-backed clamps on one mounting point.

Different angles for routing around obstructions and two clamps stacked on one bolt using a spacer.

Soft silicone inserts are also available for additional protection of sensitive cable insulation. Simply push them into the walls of the clamp before closing. The soft inserts are much easier to apply than rubber grommets on aluminium p-clamps.

Our designers also thought of something on top, which is literally on top! A saddle on top of the p-clamp makes it easy to attach hoses or leads with regular cable ties. So routing multiple cable bundles in parallel or alongside pipes and hoses is now simple.

You can see this neat feature in this introductory video:

NEW: A version of the Ratchet P-Clamp manufactured from polyamide PA66V0 is available for our rail vehicle construction customers. This material meets the fire safety requirements of the European railway standard EN 45545-2. The stainless steel mounting plate is corrosion-resistant. Please contact us here for further information

Renewable energy sources, digital information systems and the electronics behind them continue to evolve in every aspect of our lives. The complexity of the wiring schemes is increasing as a consequence.

The Ratchet P-Clamp is being used by our customers on photovoltaic installations and wind turbine towers, in trains, on ships and on all kinds of heavy duty vehicles like mobile cranes or agricultural machinery. Check out our blog story to discover more about how customers are using the Ratchet P-Clamp in their installations.

The clamp is robust and reusable and will not let you down - even in the most demanding environments or at temperatures ranging from -40 °C to +105 °C.

With the Ratchet P-Clamp, HellermannTyton gives you maximum freedom to configure your cable and hose routing just how you need it. There is no need to compromise.

Here’s a guide to help you choose the right Ratchet P-Clamp for your application.

You can choose four sizes ranging from small (A) to large (D):

HellermannTyton Ratchet P-Clamps are available in 180° straight, 15°, 30° or 90° angle variants.

Choose from short, medium or long stainless steel mounting plates.

Please note that the holes are always equidistant to the centre of the clamp, but some angle variants are not available in all three lengths.

As Ratchet P-Clamps are designed with heavy duty applications in mind, we offer four different hole sizes for use with standardised bolt sizes. You can choose between:

Cable clamps are an inexpensive means for attaching cable bundles - often in parallel to hoses or pipes. Conventional p-clamps are one-piece clips made from metal or plastic that mechanically fasten electrical cables, hydraulic hoses or pipes along their route.

Whether it is manufactured from steel, aluminium or nylon (polyamide 6.6), all these mounting clamps have one thing in common: they look like the letter ‘P’ from the side when closed, which is how they got their name.

P-clamps lock cables and hoses in place and help ensure that machinery, vehicles and equipment keep running. They bracket wires, cables or hoses together mechanically and are fastened securely to an anchor point – usually with a screw or a bolt.

Product engineers at HellermannTyton decided it was time to evolve the p-clamp design – especially for customers with heavy-duty needs. The inherent design limitations of the traditional p-clamp include the following:

Our solution to the requirements of industrial customers for a rugged clamp that adapts to different bundle diameters is the Ratchet P-Clamp.

We understand that when it comes to selecting clamps and clips, it’s often like the choice between the simple shoelace or the sophisticated buckle on a ski boot. Both do an excellent job at what they are designed for.

So if the Ratchet P-Clamp seems more like rocket science, take a look at our comprehensive range of traditional metal clamps, plastic clips and p-clamp types.

By the way, we also offer lacing cord and lacing tape if that’s what you’re looking for.

The Ratchet P-Clamps offer diverse mounting options, facilitating attachment to various surfaces. These clamps feature a self-adhesive foot part, accommodating round or oval holes, studs, and screws. Additionally, their stackable nature and integrated cable tie saddle enable the attachment of additional bundles. Furthermore, their steel mounting plates allow for different installation angles, providing versatility in mounting degrees. Ratchet P-Clamps are ideally suited for heavy-duty applications both indoors and outdoors due to their robust design and material composition.

Ratchet P-clamps are equipped with a ratcheting mechanism that locks the clamp in place once it's tightened allowing for small adjustments to the tension and ensuring a consistent hold. Conventional p-clamps typically rely on a fixed or one-time adjustment, which may require re-tightening if the cables or hoses shift.

Ratchet P-clamps are commonly used in automotive, electrical, and industrial applications where cables or hoses need to be adjusted or where a secure and reliable hold is essential.

Ratchet P-clamps are designed to provide a secure hold on cables, wires, and other items, and their effectiveness largely depends on several factors, including the quality of the clamp, the installation method, and the specific demands of the dynamic environment in which they are used. Regular inspection and maintenance are also important to address wear and tear that may occur over time. When used appropriately and in accordance with their specifications, Ratchet P-Clamps can be effective in securely holding cables and wires in dynamic settings.

Ratchet P-Clamps contribute to reducing cable strain and potential damage over time through their design and function. When properly installed and tightened, they firmly hold cables or wires in place, preventing them from moving or vibrating within their designated routes. The ratcheting mechanism allows for precise and uniform tensioning of cables, distributing the force evenly and therefore reducing the likelihood of localized stress points.

In vertical or overhead cable installations, Ratchet P-Clamps help prevent cable sag, which can lead to tension and strain on the cables below. Separately available inserts made of soft material fit precisely into the body of the clamp and thus offer increased protection for applications with movement, strong vibrations or soft cable bundles.

Ratchet P-Clamps are adaptable solutions that can accommodate a wide range of cable shapes and sizes. Their adjustability, availability in different sizes, and options for cushioning materials make them versatile for securing round, flat, bundled, or irregularly shaped cables. Cables, regardless of their composition, are automatically fixed or centered in the middle of the clamp.