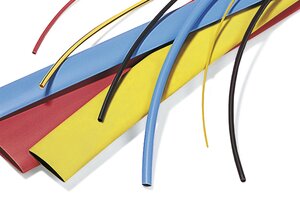

Heat shrinkable tubing 2:1 - flexible and coloured

Art.-No. 309-65106

| TFN21-ST 1.6/0.8-PO-X-GN

|

Copied

- High shrink ratio (2:1)

- Few sizes cover a wide range of diameters allowing reduced inventory

- Thin wall, flexible polyolefin tubing

- Fast shrinking and low shrink temperature

- Flame-retardant, UL224 VW1 listed

More products in this product group:

| Application | TFN21 is suitable for a wide range of applications like electrical insulations, mechanical protection and cable bundling. |

| Behaviour At Low Temperature | not cracking |

| Behaviour at Heat Shock | not cracking, not breaking, not fluid |

| Behaviour at low Temperature test method | UL 224 |

| Colour | Green (GN) |

| Elongation At Heat Aging | 700% |

| Heat Aging Test | 168h/175°C |

| Heat Aging test method | UL 224 |

| Heat Shock Test | 4h/250°C |

| Material | Polyolefin, cross-linked (PO-X) |

| Minimum Tensile Strength At Heat Aging | 13.5MPa |

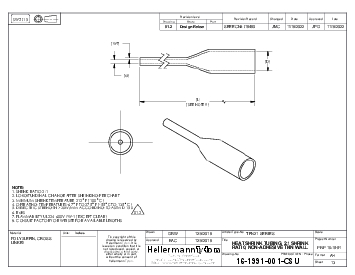

| PART DESCRIPTION | TFN21-ST 1.6/0.8-PO-X-GN |

| Package Content | 20pcs. |

| Package Content packed in | pack |

| Printable | No |

| Product Family | TFN21 |

| Product Group | Heat shrinkable tubing 2:1 - flexible and coloured |

| Shrink Ratio | 2:1 |

| Type | TFN21-ST 1.6/0.8 |

| Variant | Thin-Wall |

| With inner glue (Yes/No) | No |

| CSA Certified | Yes |

| Dielectric Strength | 20kV/mm |

| Dielectric Strength test method | ASTM D150 |

| Elongation at break (min.) | 600% |

| Elongation at break test method | ASTM D2671 |

| Flammability | UL 224 VW-1 |

| Halogen-free | No |

| Min. Shrink Temperature - °C | +70 °C |

| Operating Temperature | -55 °C to +135 °C |

| ROHS compliant | Yes |

| Specifications |

|

| Specifications | ANSI/UL 224, CSA |

| Tensile Strength | 14MPa |

| Test Method Tensile Strength | ASTM D2671 |

| UL File link | Link Link |

| UL Listed (US and Canada) | No |

| UL Listed (US and Canada) | No |

| UL Recognized (US and Canada) | Yes |

| UL Recognized (US) | Yes |

| UL-File Number | E125182 |

| Volume Resistance | 10¹⁴ Ω cm |

| Volume Resistance test method | UL 224 |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download

TFN21 1.6/0.8-PO-X-GNYE

309-60100

TFN21 1.6/0.8-PO-X-GNYE

309-60100 TFN21 1.6/0.8-PO-X-BK

309-60101

TFN21 1.6/0.8-PO-X-BK

309-60101 TFN21 1.6/0.8-PO-X-RD

309-60103

TFN21 1.6/0.8-PO-X-RD

309-60103 TFN21 1.6/0.8-PO-X-YE

309-60104

TFN21 1.6/0.8-PO-X-YE

309-60104 TFN21 1.6/0.8-PO-X-BU

309-60105

TFN21 1.6/0.8-PO-X-BU

309-60105 TFN21 1.6/0.8-PO-X-GN

309-60106

TFN21 1.6/0.8-PO-X-GN

309-60106 TFN21 1.6/0.8-PO-X-CL

309-60107

TFN21 1.6/0.8-PO-X-CL

309-60107 TFN21 2.4/1.2-PO-X-BK

309-60118

TFN21 2.4/1.2-PO-X-BK

309-60118