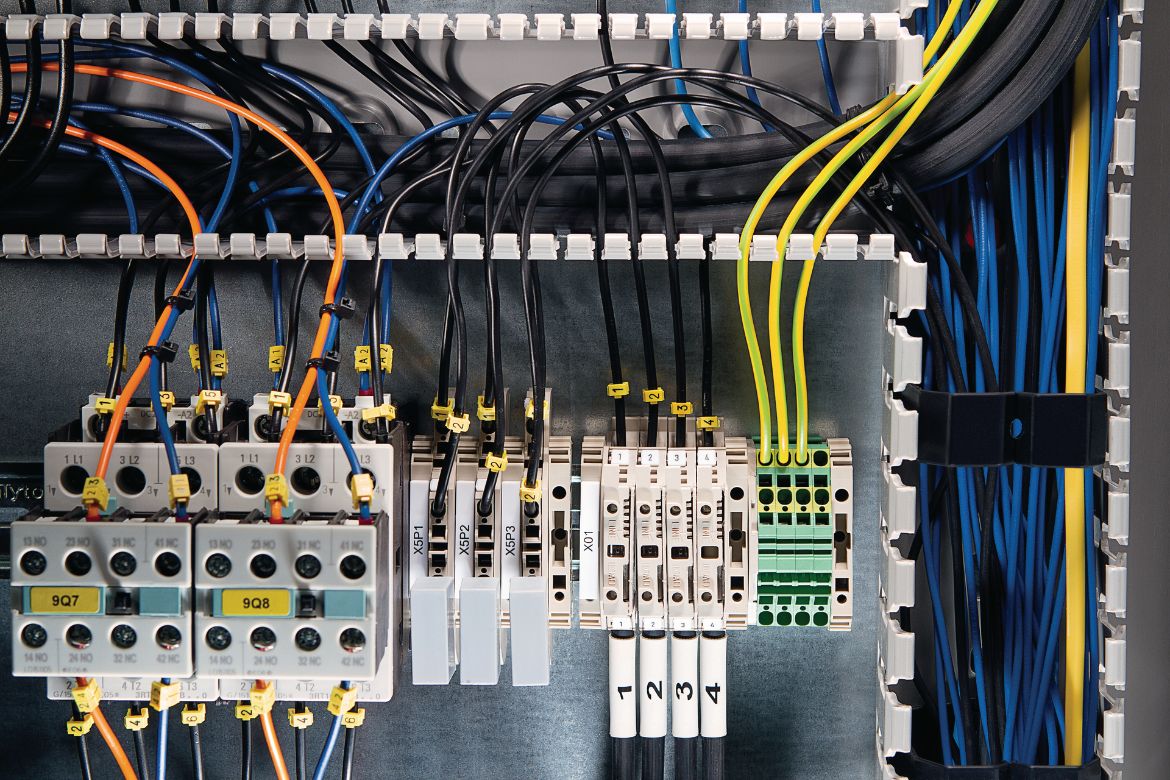

HellermannTyton’s HelaDuct PVC and halogen-free PC/ABS wiring ducts are designed to maximise the use of space in the electrical cabinet. The range covers six widths from 25 mm to 120 mm and four heights from 40 mm to 100 mm.

“It’s not only the variety of sizes and combinability that are important to HelaDuct,” explains Michael Goslinowski, Area Sales Manager at HellermannTyton in Germany. “The processing quality of the wiring ducts also meets the expectations of the cabinet builder. Thanks to predetermined breaking points, the fingers and wall segments can be removed burr-free all the way to the bottom, saving time and requiring no special tools. Smooth edges – especially in the HF area – protect the installer's hands.”

“The processing quality of the wiring ducts also meets the expectations of the cabinet builder.“

Keep a lid on it

HellermannTyton also counteracts one of the most common neuralgic points in the design of wiring ducts: the lid that won't hold.

“HelaDuct lids always hold securely and flush, whether mounted vertically, upside down or under the influence of vibration. Even the lids of the stiffer halogen-free material hold firmly. These can nevertheless be pulled upwards particularly easily and with the right handle, even in tight installations,” enthuses Goslinowski.

“HelaDuct lids always hold securely and flush, whether mounted vertically, upside down or under the influence of vibration.“

Useful add-ons

During installation or maintenance, cables tend to fall out as soon as the cover is removed. This increases the time spent by the electrical engineer immensely. For this reason, accessories such as the wire retaining clip HTWD-NFWR are included in the system solution. It can be clicked onto the webs of all types of trunking. It is easy to break off to the desired length at their predetermined breaking points, and it holds particularly securely. This really makes work easier and gives a more professional impression than converted rubber bands or pieces of wire.

“That couldn’t be more convenient,” says Goslinowski.

For the HelaDuct PVC trunking, HellermannTyton offers further fixing material that can be easily anchored in a patented bottom hole. In these raised mounting points, the HTWD-CTH cable tie spacer base and HTWD-BWR wire retaining clip can be mounted with a quarter turn of a screwdriver before or after the trunking is fixed in the electrical cabinet. “These special accessories help the electrical engineer prevent cables in the wiring duct from pressing against the cover from the inside, or from jumping out when it is opened. That couldn’t be more convenient,” says Goslinowski.