Engineered for land, air, and naval platforms: HellermannTyton delivers certified solutions for cable protection, insulation, identification, and fastening in military systems worldwide, including abrasion-resistant heat-shrink tubing, EMI shielding sleeves, and heavy-duty cable ties for defence. Each part is engineered to deliver reliable performance in the most demanding environments.

From rapid prototyping to serial production and full lifecycle support, our globally recognised processes ensure seamless integration and compliance with MIL-SPEC, NATO, EN, and VG standards.

We provide full defence industry certifications and documentation for audit readiness, giving you peace of mind for every project.

Whether you need aircraft wire systems, marine cable protection, or military wire harness solutions, we help you accelerate timelines, reduce risk, and maintain operational readiness – with speed, precision, and reliability.

Need guidance selecting the right defence cable solutions for land, sea, or air applications?

Compliance is the foundation of trust in military and defence cable management. Every cable solution – from heat shrink tubing to EMI shielding sleeves and MIL-SPEC cable ties – must meet strict international standards to ensure safety, reliability, and audit readiness.

Our products are certified to:

Complete documentation and traceability support audits and qualification processes – ensuring that military cable management solutions integrate seamlessly into land, naval, and aerospace platforms.

Modern land combat systems and field support equipment require cable management solutions engineered to withstand:

These capabilities ensure secure, resilient, and maintainable cable infrastructure across modern land systems.

Core competencies are designed to address key defence challenges, such as reducing lead times, strict compliance requirements, lifecycle support, and the need for scalable, resilient solutions.

The approach combines technical excellence, operational efficiency, and strategic partnership – supporting projects from development through ramp-up to operational sustainment.

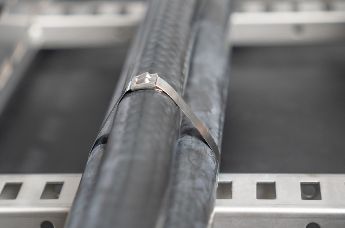

In military land systems, cables must remain secure under constant vibration and mechanical stress to prevent mission-critical failures.

To meet these requirements, the following solutions provide the durability and performance demanded in defence environments:

Signal integrity is vital in combat environments where electromagnetic interference can disrupt sensitive electronics.

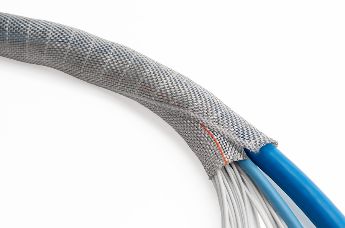

To ensure reliable performance in these demanding conditions, the following shielding and protection solutions provide the required level of EMI resilience:

Clear cable identification ensures fast maintenance and full compliance with military standards.

Efficient installation under operational time pressure requires ergonomic tools built for the demanding environments of land combat systems and armoured platforms.

Naval and maritime defence platforms face unique challenges: saltwater corrosion, vibration, confined spaces, and strict compliance requirements.

Every component must deliver long-term reliability under extreme conditions while meeting standards such as MIL-SPEC, VG, and certifications from Lloyd’s Register or DNV GL.

Marine environments demand defence industry cable solutions that resist corrosion, chemicals, and mechanical stress over decades of service.

Reliable sealing and strain relief are critical to protect mission-critical systems from ingress and shock.

Electromagnetic interference can compromise sensitive naval electronics – shielding is essential.

Clear, durable marking ensures compliance and simplifies maintenance in complex naval systems.

Space constraints and time‑critical installations aboard naval vessels and marine military systems require highly efficient and reliable assembly solutions.

Aerospace platforms demand cable management that is lightweight, space-efficient, vibration-resistant, and fully compliant with stringent safety and performance standards. From take-off to landing, reliability is non-negotiable – and every component must meet aerospace-specific certifications such as AS9100, RTCA/DO-160, and MIL AS85049.

Weight reduction without compromising safety is critical in aircraft and UAV applications.

Avionics and power distribution systems require components that guarantee signal integrity and compliance.

Aerospace environments expose cables to vibration, moisture, chemicals, and temperature extremes.

Clear identification for defence industry cable solutions ensures maintenance efficiency and regulatory compliance throughout the flight lifecycle.

Every component must deliver dependable performance from initial integration to long‑term maintenance across aerospace and defence platforms – including commercial, military and unmanned aircraft.

Defence programs often move from low-volume prototypes to high-volume production at short notice – agility and speed are critical for defence industry cable solutions.

Whether you need a single prototype or a full fleet rollout, we deliver defence industry cable management solutions with speed, precision, and reliability – helping you stay ahead of operational demands.

Our scalable approach ensures readiness for every phase of cable management:

Defence industry cable solutions must address extreme environmental conditions, electromagnetic interference (EMI), strict compliance requirements, and the need for rapid deployment and maintenance. Solutions must be robust, reliable, and certified for use in land combat systems, marine defence cable solutions, and aerospace cable assemblies.

Key product groups for defence applications include:

All products comply with MIL-SPEC, VG, and NATO STANAG standards, supported by full documentation and certifications for military.

A reliable defence cable solution supplier should offer:

Choosing a supplier with these qualities ensures mission-critical reliability, compliance, and operational efficiency for land, naval, and aerospace platforms.

Key standards include MIL-SPEC wiring harness, MIL-STD for cable harness, DEF STAN, VG, NATO STANAG, EN, and UL. For quality management: ISO 9001, AS9100, and IATF 16949. Compliance with RoHS and REACH is also essential.

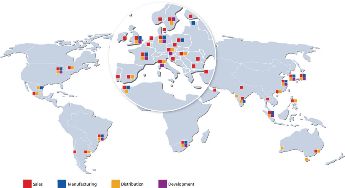

Yes – we offer rapid prototyping, co-engineering, and scalable production for military cable assemblies, heat shrink tubing for defence, and EMI shielding sleeves across 18 global sites.

With over 40 national organisations, 18 production sites, and robust local stockholding, we guarantee short lead times for MIL-SPEC cable ties, marine heat shrink tube, and other mission-critical components.

Yes – including retrofit kits, MIL-SPEC wiring harness upgrades, and full compliance documentation for audits.

Download our Defence Brochure for comprehensive product information and compliance details.