The automotive industry is rapidly evolving, driven by electrification, autonomous system electronics, and the need for efficiency. As vehicle architectures evolve, fluid routing management has become mission-critical.

Modern electric and hybrid vehicles need advanced fluid routing solutions (FRS) to manage both flexible and rigid multi-loop coolant circuits and high-pressure lines in theit complex thermal management sytsems (TMS).

Engineers have to integrate multiple fluid systems – coolant, brake, fuel, cleaning and HVAC lines – within dense packaging spaces, while meeting strict safety, sustainability, regulatory, and cost requirements.

Optimal bend radius, minimal noise, vibration, harshness (NVH) and thermal homogeneity are prerequisites for system reliability and occupant comfort. Precise, lightweight and robust fluid fasteners, holders and retainers are essential.

To achieve the right FRS results, automotive OEM and Tier 1 suppliers need a partner with advanced design and material know-how and strong regional production capabilities – like HellermannTyton – to engineer fluid routing solutions that expertly navigate around sensor exclusion zones, crash safety areas, and densely packed electronic components.

We work collaboratively with our customers' engineers to help them address all their vehicle platform needs with the most efficient, performant and cost-effective fasteners, in all the right places – utilising the wide spectrum of interface possibilities

HellermannTyton's expertise in automotive plastic fasteners, retainer clips, and custom-engineered routing components puts us in an ideal position to help enable efficient, compliant, and serviceable fluid routing management.

Every plastic component – off-the-shelf or custom – is engineered for lightweight strength, easy assembly, and durability. Smart design and material selection ensure thermal and chemical resistance, impact protection, vibration dampening and acoustic isolation of media-carrying lines.

HellermannTyton's Key Account Manager, Walter Alexander Warnecke, talks about the special challenges of fluid fastening and the increasing engineering complexity for OEMs.

→ Order free samples here of the latest HellermannTyton standard parts for fluid routing management

HellermannTyton recommends a variety of clip and clamp designs to hold media-carrying lines along vehicle structures, enabling quick mounting and push-in installation. A key advantage of these solutions is how easily they can be combined and assembled together, giving you all the flexbility you need from a custom part, but with an off-the-shelf solution that is available immediately.

Modular Omega Clips (MOC) are commonly used in fluid systems such as fuel, brake, vacuum, and cleaning fluid lines, as well as in combination with wiring harnesses, HVAC systems, and powertrain thermal management. Use cases also include engine venting, fuel vapor recovery, battery cooling, and air conditioning lines, as well as screen, sensor and camera cleaning fluid hoses. Their modular architecture – with 12 distinct variants – facilitates excellent configuration flexibility.

The MOC Series combines the benefits of clips and ties and is paired with mounting options including edge clips, fir trees, stud mounts, and extenders for larger offsets – as well as ties and other MOCs and LOCs – providing a comprehensive routing solution.

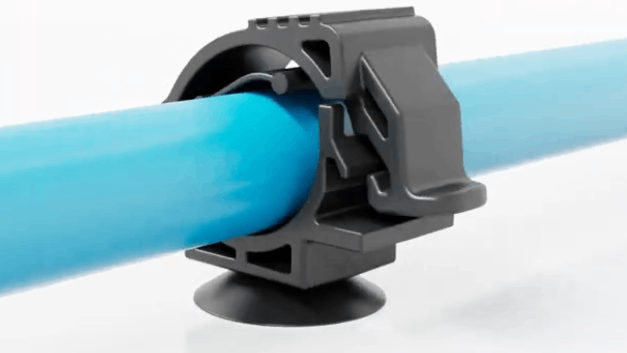

Locking Omega Clamps (LOC) prioritise secure locking and reusability. They are often a good fit for the same fluid routing scenarios MOC clips cover, but with the added benefit of a 360° locking with no axial slip, and an adjustable mechanism for varying bundle diameters. In combination with cable ties, LOC clips cater to a broad diameter range up to 48 mm and can be reopened and closed for servicing.

Create exactly the right off-the-shelf product for your routing needs

→ Go to the MOC Configurator

Clamps are common components in modern vehicle design, ensuring secure and efficient routing of hoses and tubes throughout the chassis. Adjustable Clamps simplify installation by allowing technicians to fasten lines quickly and confidently, even in tight or complex packaging spaces. Whether fastening underbody lines, thermal management houses, or high-voltage harnesses in electric vehicles, HellermannTyton’s unique ratcheting clamps accomodate a wide range of diameters in a single fastener. Available with or without stand-offs and in multiple interface mounting options, they provide engineers with the flexibility needed to meet diverse routing requirements.

Engineered to meet the demanding requirements of modern vehicle assembly, our parallel cable holders feature an oval housing for welding studs, enabling tolerance compensation during installation. This ensures a secure and reliable fit, even in tight or complex automotive mounting environments. Thanks to its soft-push design, the part is easy to install without any tools, saving time and enhancing operator comfort during vehicle assembly.

If you prefer a solution with ties, rather than clips or clamps, HellermannTyton also offers a wide range of automotive fixing ties for multiple line fastening on all types of interfaces.

In addition to our specialisation in edge clips for use with cable ties, we also offer a dedicated range of EdgeClips for pipes and hoses of various diameters. These compact edge fixing elements for tubes are simple to push onto an available edge by hand. Once positioned, the integrated clamp closes securely with a distinct, reassuring click, ensuring that pipes and hoses remain firmly in place even under constant vibration or thermal cycling.

The design supports effortless re-opening whenever required, giving technicians easy access without compromising the attachment point. Thanks to their robustness, corrosion resistance, and versatility across a wide range of edge thicknesses, HellermannTyton EdgeClips provide a highly efficient, cost-effective solution for routing fluid lines in tight or complex installation environments.

Corrugated and convoluted tubing is widely used in automotive fluid routing to shield lines from abrasion, heat, and movement—especially in tight packaging spaces around HVAC, underbody sections, and thermal management loops.

HellermannTyton’s specialised retainer clips and clamps for corrugated tubes secure these protective sleeves without compressing or deforming them, ensuring unrestricted flow and preventing slippage even under vibration and dynamic load.

Designed for fast, tool-free installation and available in multiple interface options, these fastening solutions help engineers route fluid lines safely, cleanly and efficiently across the vehicle architecture.

Looping, threading, tensioning and cutting off ties at the press of a button and with consistent quality? That’s what HellermannTyton Autotool systems are designed to do.

The ATS flex cable tie gun applies ties and fasteners to fluid lines with speed, accuracy and consistency. It can be integrated into fully automated confectioning processes, or used flexibly on the production line.

Key benefits of the ATS flex for the automotive industry:

1. Faster processing: assembly time cut by up to 70% (e.g. 2.4 sec vs. 8 sec manually)

2. Consistent results: automatic calibration and integrated process control

3. Flexible set-ups: integrate into automated production or use bench-mounted or suspended

4. Greater safety: protects hoses from overtightening and operators from strain

5. Material efficiency: the exact tie strap amount is used, reducing waste and disposal costs.

The 2-component Soft Grip Series, made from PA66HS and TPE, is specially designed to secure sensitive bundles like fluid-carrying hoses in automotive applications. This cable tie ensures enhanced protection where it matters most – especially in areas exposed to vibration or movement, where NVH is an issue.

A key feature of the design is a soft TPE inner layer that cushions and stabilises the bundle, preventing lateral movement without compromising the integrity of smooth tubing surfaces. This makes it ideal for use in fluid routing systems, where traditional ties may slip, cause abrasion, or contribute to unwanted noise.

The pre-locking mechanism allows the cable tie to be held in position on the bundle before final tensioning, simplifying assembly processes and improving installation accuracy. Thanks to their soft TPE inner layer, Soft Grip ties ensure a high level of protection with a secure grip that prevents lateral slippage even on smooth tubing.

Interchangeable foot parts make this a versatile off-the-shelf fluid routing fastening solution. The EVO9 SG application tool ensures consistent tensioning and the flush cuts that are essential in automotive assembly.

Order a free Soft Grip Sample Pack and test this unique product in your next project.

Reliable fluid routing ensures consistent coolant flow to prevent overheating or overcooling that can cause efficiency losses or failure.

Effective thermal management is vital for performance, efficiency, safety and component life. In battery electric (BEV) and hybrid electric (HEV) systems, powertrains, regenerative braking and charging generate significant heat, while battery operating temperature must be maintained within a strict range – ideally between 20˚C and 40˚C.

Like in electric vehicle (EV) systems, precise fluid routing in internal combustion engine (ICE) vehicle systems maintains optimal engine temperature, avoiding excess fuel use, oil degradation or component damage. By directing coolant through key areas, well-designed systems enable efficient heat transfer, balance thermal loads and optimise energy use.

Lighter vehicles require less energy to move and have a greater range. "Overall, lighter vehicles are more economical and better for the environment”, says Arthur Zemanek, Sales Manager Automotive. HellermannTyton's design and manufacturing expertise can help cut FRS component weight by up to 70%, and improve sustainability and simplify installation – without compromising strength and performance reliability.

HellermannTyton offers proven solutions for both brake and fuel line applications.

Precise routing is critical to maintain consistent hydraulic pressure, minimise heat exposure and prevent vibration-related wear or fatigue of hydraulic lines that carry brake fluid from the master cylinder to the callipers or wheel cylinders.

Releasable Ratchet O-Clamps, featuring soft TPE over moulding, prevent axial slip and support good NVH. This standard part family is related to our long experience producing bespoke brake line fasteners.

Good routing choices prevent kinks, leaks or pressure loss – all of which compromise braking performance and safety.

Fuel line routing plays a vital role in delivering fuel from the tank to the engine and related components. Lines must be positioned to avoid heat sources, sharp bends and vibration-prone areas to prevent vapour lock, leaks or abrasion. Efficient routing also supports compliance with safety and emissions standards while simplifying assembly and maintenance. For complex layouts, Modular Omega Clips (MOC) and Locking Omega Clamps (LOC) deliver near-custom routing without the delays or cost of bespoke designs.

Efficient fluid routing in heating, ventilation and air conditioning (HVAC) systems is essential for reliable thermal transfer and energy performance.

Optimised HVAC hose fastening can prevent pressure drops, flow imbalance and heat loss, which otherwise impact energy consumption and placing unnecessary strain on compressors, pumps and valves. Refrigerant, coolant and condensate lines must avoid interference with other components, remain accessible for service and withstand extreme temperature ranges without material degradation.

Our solutions are engineered to resist corrosion, vibration and chemical exposure while helping reduce NVH transmission into the cabin.

Explore how the shift to EV is reshaping the demands of wire and fluid management.

Dive into how HellermannTyton is helping OEMs reduce weight, maximise range and automate with smarter routing solutions.

Yes, fluid system pre-confection can be automated using HellermannTyton automatic cable tying systems which can be integrated it into semi- or fully automated production. For example, the ATS flex system streamlines bundling and fastening of pipes and hoses with waste-free, repeatable electromechanical precision, reducing assembly time by up to 70%. HellermannTyton also offers the advanced FTS pro Autotool system for scenarios involving high-volume automatic application of one-piece fastening ties. The tool system supports full data logging and can be integrated with robotic systems for complete process control and traceability. Contact our Tool System Team to discuss options.

Selecting the right fastener depends on the line material (rubber hose, aluminium pipe, corrugated tube, etc.), operating temperature, and required retention force. HellermannTyton offers a broad range of clips, clamps, ties and holders that accommodate diverse diameters and bundle shapes. Solutions such as Modular Omega Clips (MOC), Locking Omega Clamps (LOC), Ratchet Clamps and Soft Grip ties provide flexibility across multiple sizes without the need for bespoke tooling. Our experts can help identify the optimal interface – edge, stud, hole, or harness – based on your packaging space and application constraints.

Automotive fluid systems expose fastening components to coolant, fuel, refrigerant, oils, salts, and extreme thermal cycles. HellermannTyton components are engineered from high-performance polymers that offer excellent thermal stability, chemical resistance and long-term durability. The materials prevent degradation, maintain clamping force under vibration, and withstand moisture and corrosion – making them ideal for engine bays, underbody environments and EV thermal loops. We also advise on materials that contribute to CO2 reduction goals – be that PP vs PA6.6, or integration of recycled material.

Absolutely. NVH management is essential for comfort and system performance, particularly in modern EV architectures. HellermannTyton fasteners incorporate features such as soft TPE inserts, dampened interfaces and secure anti-slip mechanisms that stabilise lines and prevent rattling. The result is smoother coolant flow, reduced mechanical noise transfer and more reliable thermal system behaviour under dynamic loads.

Yes. HellermannTyton fasteners are engineered to support the complex multi-loop coolant circuits of EV and HEV platforms, including battery cooling, power electronics thermal management and HVAC refrigerant routing. At the same time, they are equally suited to ICE applications such as engine cooling, fuel delivery and brake line routing. Their modularity, temperature resilience and vibration control make them ideal for mixed-platform vehicle families.

Certainly. In addition to our extensive portfolio of off-the-shelf clips, clamps and fixing ties, HellermannTyton also develops customer-specific routing components tailored to individual vehicle architectures, like, for example, bespoke air intake ducts for enhanced brake cooling. Our teams work directly with OEM and Tier 1 engineers to account for packaging constraints, sensor exclusion zones, crash requirements, thermal loads and sustainability goals. Custom solutions can combine multiple functions into a single lightweight component, reducing weight, complexity and assembly time.

The hydrogen economy relies on highly reliable fluid management, as hydrogen must be conveyed and controlled safely under varying pressures and temperatures. Secure routing, robust sealing and vibration‑stable support are essential for maintaining system integrity in H₂ infrastructure and fuel‑cell applications. HellermannTyton provides fastening solutions engineered for stable, abrasion‑free routing lines in different diameters and dynamic temperature ranges. Our lightweight, chemically resistant clips and clamps minimise movement, protect sensitive tubing and maintain long‑term durability under high pressure and thermal cycling.

We are happy to put you in touch with your local HellermannTyton automotive industry expert for advice and support.