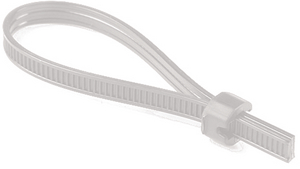

Automatic cable tie tool Dmax=100.0mm, for 4.5mm, 2.068kg, black

Art.-No. 102-00000

| ATS3080-MET/PL-BK

Copied

This product is not available anymore.

Alternative product available

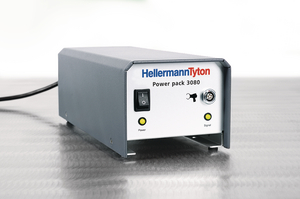

- Electrically operated cable tying system (Power pack 3080 necessary)

- Power supply through Power pack 3080 - Input: 240/150 V a.c., 50/60 Hz; Output: 48 V d.c., max. 150 W

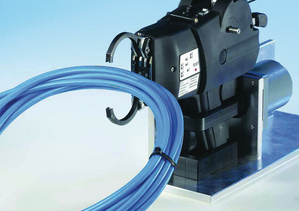

- High quality, waste-free bundling up to ⌀ 100 mm with flush cut off

- Jaws with diameters of 30, 50 and 80 mm - included in delivery,

- 100mm jaw size solution as accessory on request

- Cycle time 1.1-2.4 seconds depending on bundle diameter

- Bundle diameter mechanically detected

- Integration into Bench mount kit 3080 or Overhead suspension 3080 possible

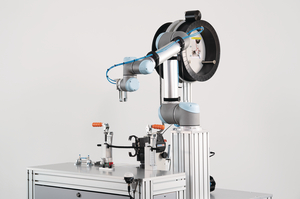

- Integration into fully automated production lines possible

- Foot part bundling with custom jaw design ⌀ 50 mm

More products in this product group:

| Application |

The Autotool System 3080 is an automated and electric cable tying system. It has been developed to speed up bundling processes and operates waste-free. The advantage of three quick-changeable jaw sizes allows the Autotool System 3080 to adapt perfectly to different bundle diameters up to ⌀ 100 mm. With either the Bench mount kit 3080 or the Overhead suspension 3080, the Autoool System 3080 is suitable for both stationary and flexible applications. The Autotool System 3080 can also be integrated into fully automated production lines. Custom designed jaws are available to enable bundling of foot parts on production lines. |

| Application Method | Stationary or flexbile |

| Bench mount kit | Tool and tie reel stand including footpedal |

| Colour | Black (BK) |

| Cycle Time | 1.1-2.4 sec. depending on bundle diameter |

| Description | Autotool System 3080 |

| For Cable Tie Width | 4.5 - 4.5mm |

| For Ties | ATS3080 |

| Harness board accessory HH20 | Raises the bundle off the harness board at optimum height and allows the operator to eliminate handling the bundle when applying ties. |

| Material | Metal (MET), Plastic (PL) |

| Operation | electrical |

| Overhead Suspender | Overhead suspension 3080 and tie reel stand including balancer |

| PART DESCRIPTION | ATS3080-MET/PL-BK |

| Package Content | 1pc. |

| Package Content packed in | case |

| Power Supply | Electrically operated |

| Power Supply unit | Input: AC 100 V - 230V, 3A 50/60 Hz, Output: 48 V d.c., 100 W |

| Product Family | Autotool System ATS |

| Product Group | Waste-free bundling up to ⌀ 100 mm |

| Short Description | Automatic cable tying system ATS3080 |

| Strap Thickness max. | 1.2mm |

| Tool property | Automatic cut off |

| Tool suitable cable tie material | Plastic |

| Type | ATS3080 |

| UV-Stabilised | No |

| Weight/Unit | 2.068kg |

|

|

|

| Country of Origin | DE |

| Customs Number | 84672985 |

| GTIN-13 / EAN | 4031026215822 |

| Packaging 1 - Height (m) | 0.145m |

| Packaging 1 - Length (m) | 0.471m |

| Packaging 1 - Qty | 1 |

| Packaging 1 - Type | pcs. |

| Packaging 1 - Volume (m³) | 0.02636187m³ |

| Packaging 1 - Weight (kg) | 5.168kg |

| Packaging 1 - Width (m) | 0.386m |

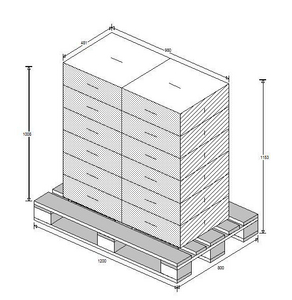

| Packaging 3 - Height (m) | 0.168m |

| Packaging 3 - Length (m) | 0.481m |

| Packaging 3 - Qty | 1 |

| Packaging 3 - Type | box |

| Packaging 3 - Volume (m³) | 0.0396m³ |

| Packaging 3 - Weight (kg) | 4.56kg |

| Packaging 3 - Width (m) | 0.49m |

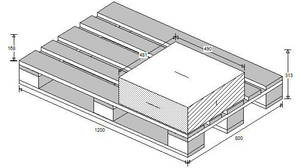

| Packaging 4 - Height (m) | 1.152m |

| Packaging 4 - Length (m) | 1.2m |

| Packaging 4 - Qty | 10 |

| Packaging 4 - Type | pallet |

| Packaging 4 - Volume (m³) | 1.106m³ |

| Packaging 4 - Weight (kg) | 66.6kg |

| Packaging 4 - Width (m) | 0.8m |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

1 x SP_ATS_front_cap_cpl.

102-31000

1 x SP_ATS_front_cap_cpl.

102-31000

Download

Download

Closures_Natural_ATS

102-66209

Closures_Natural_ATS

102-66209 Closures_Black_ATS

102-66210

Closures_Black_ATS

102-66210 Overhead_suspension_ATS

102-00050

Overhead_suspension_ATS

102-00050 Bench_mount_kit_ATS

102-00040

Bench_mount_kit_ATS

102-00040 SP_ATS_spring_flaps_upper_jaw

102-00901

SP_ATS_spring_flaps_upper_jaw

102-00901 SP_ATS_flap_lower_jaw_right_cpl.

102-00910

SP_ATS_flap_lower_jaw_right_cpl.

102-00910 SP_ATS_flap_lower_jaw_left_cpl.

102-00920

SP_ATS_flap_lower_jaw_left_cpl.

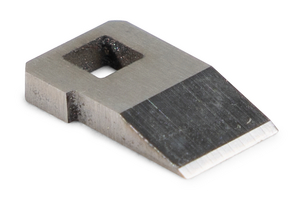

102-00920 SP_ATS_tail_cutter

102-31003

SP_ATS_tail_cutter

102-31003