HUS876 2.4/1.2-PO-X-BK

Art.-No. 301-60240

| HUS876 2.4/1.2-PO-X-BK

Copied

- HUS876 tubing has UL-224 VW1 approval, ensuring a high level of flame retardancy.

- It is easy to apply because it has a high degree of flexibility and also has good mechanical and chemical properties.

- It is also possible to print onto HUS876 tubing.

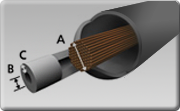

| Application | HUS876 is used where high flame retardany is required. It is very versatile because of its good mechanical and chemical properties, so it is used for insulation, mechanical protection, strain relief and marking. |

| Behaviour At Low Temperature | not cracking, not breaking |

| Behaviour at Heat Shock | not cracking, not fluid, not breaking |

| Behaviour at low Temperature test method | ASTM D2671 |

| Color | Black (BK) |

| Elongation At Heat Aging | 400% |

| Heat Aging Test | 168h/175°C |

| Heat Aging test method | ISO 37 |

| Heat Shock Test | 4h/250°C |

| PART DESCRIPTION | HUS876 2.4/1.2-PO-X-BK |

| Packaging Type | meter |

| Part No. | 301-60240 |

| Product family | Insulation |

| Type | HUS876 2.4/1.2 |

| Dielectric Strength | 20kV/mm |

| Dielectric Strength test method | ASTM D150 |

| Elongation at break (min.) | 400% |

| Elongation at break test method | ISO 37 |

| Material | PO-X |

| Material | Polyolefin, cross-linked (PO-X) |

| Min. Shrink Temperature | +185 °F (+85 °C) |

| Operating Temperature | -67°F to +275°F (-55°C to +135°C) |

| REACH Conformity | No |

| ROHS compliant | Yes |

| Test Method Tensile Strength | ISO 37 |

| UL File Number [Logo] | E143529 [RU] |

| UL Recognized (US) | Yes |

| Volume Resistance test method | ASTM D2671 |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download