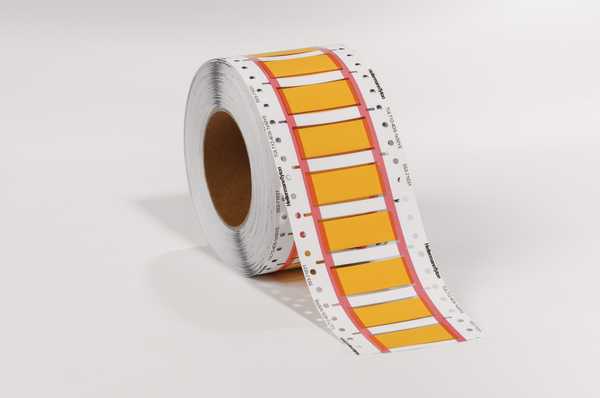

Heat shrink marker, flame retardant/chemical resistance, thermal transfer print, ladder-style, 12.0mm/4.0mm, W=16mm, yellow, 1500pcs.

Art.-No. 553-71035

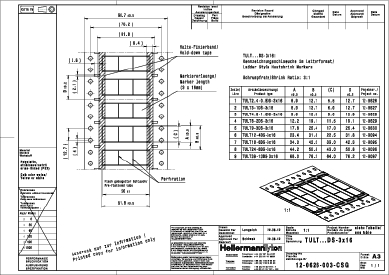

| TULT12-4DS-3x16YE-PO-X-YE

Copied

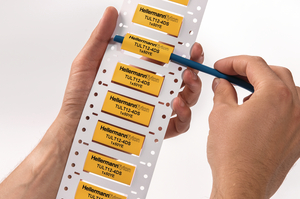

- TULT DS is a 3:1 heatshrink material pre-cut and formatted onto a convenient 'ladder' system that allows printing on both sides of the marker.

- The product is military specified for use on military grade equipment.

- TULT DS ShrinkTrak is flame rated to UL224-VW-1 for use with fire rated wire and cable and related equipment.

More products in this product group:

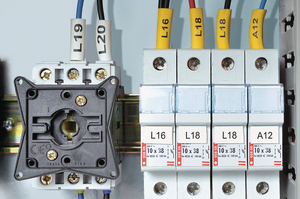

| Application | TULT DS is a UL recognised 3:1 heat shrink marker material pre-cut and formatted into a convenient "ladder" system. This pre-cut format not only allows printing on both sides of the marker but the user can also easily choose and pick each required marker. TULT’s polyolefin compound has good mechanical strength and resistance to organic solvents and chemicals. The surface of the tubing has been especially prepared so that print performance is excellent at all times using HellermannTyton's printer range. |

| Behaviour at low Temperature test method | ASTM D2671 |

| Brand Family | TULT DS |

| Color | Yellow (YE) |

| Description | TULT DS is a double sided ShrinkTrak designed for use in military approved applications, where Mil-Spec approval is required. The marker meets all applicable military standards and is flame rated to UL224 WV-1. |

| Heat Aging Test | 168h/175°C |

| Heat Aging test method | ASTM D638 |

| Heat Shock Test | 4h/250°C |

| Key product features | flame retardant, chemical resistance, UV resistant |

| PART DESCRIPTION | TULT12-4DS-3x16YE-PO-X-YE |

| Packaging Type | carton |

| Part No. | 553-71035 |

| Print Method | thermal transfer print |

| Print Method (Alternative) | laser beam print |

| Product family | Identification Systems |

| Short Desc. | TDRT DS-2S ShrinkTrak, Military Grade, 0.63" x .86", Polyolefin, Yellow, 1,500/PK |

| Type | TULT12-4DS-3x16YE |

| Fixation Method | Suspend |

| Longitudinal Change After Shrinkage | -15% max. |

| Longitudinal Change After Shrinkage | ASTM D2671 |

| Printable | Yes |

| Recovered Diameter (imperial) | 0.16" |

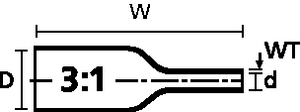

| Recovered Diameter (metric) | 4.0mm |

| Shrink Ratio | 3:1 |

| Supplied Diameter (imperial) | 0.47" |

| Supplied Diameter (metric) | 12.0mm |

| Volume Resistance | 10¹⁶ Ω cm |

| Wall Thickness (imperial) | 0.033" |

| Wall Thickness (metric) | 0.68mm |

| Width (imperial) | 0.63" |

| Width (metric) | 16mm |

| Dielectric Strength | 20kV/mm |

| Dielectric Strength test method | ASTM D2671 |

| Elongation at break (min.) | 300% |

| Elongation at break test method | ASTM D638 |

| Flammability | UL 224 VW-1 |

| Halogen Free | No |

| Material | PO-X |

| Material | Polyolefin, cross-linked (PO-X) |

| Min. Shrink Temperature | +194 °F (+90 °C) |

| Operating Temperature | -67°F to +275°F (-55°C to +135°C) |

| REACH Conformity | No |

| ROHS compliant | Yes |

| Reel Variant | ladder-style |

| Test Method Tensile Strength | ASTM D638 |

| US MILSPEC | MIL-STD-202H Method 215K |

| Volume Resistance test method | ASTM D257 |

Argentina

Argentina Australia

Australia Brazil

Brazil Bulgaria

Bulgaria China

China Czech Republic

Czech Republic Denmark

Denmark Finland

Finland France

France Germany

Germany Hungary

Hungary India

India Italy

Italy Netherlands

Netherlands North America

North America Norway

Norway Poland

Poland Portugal

Portugal Romania

Romania Russia

Russia Singapore

Singapore Slovenia

Slovenia South Africa

South Africa South Korea

South Korea Spain

Spain Sweden

Sweden Switzerland

Switzerland Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom

Download

Download

TT431

556-00400

TT431

556-00400 TTDTHOUT 60MM

556-00140

TTDTHOUT 60MM

556-00140 TT4030

556-04037

TT4030

556-04037 TT4030DS

556-04061

TT4030DS

556-04061